This entrepreneur is building Covid care hospitals in rural areas of North India

Shriti Pandey, 29, is helping construct health care facilities at a faster pace in remote locations using sustainable materials derived from agricultural waste

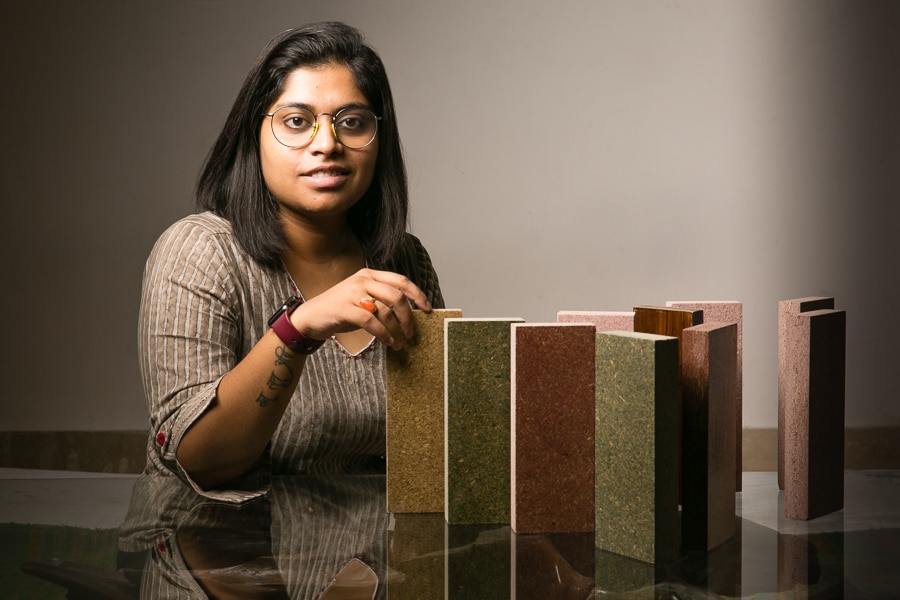

Shriti Pandey, founder, Strawcture Eco with the agri bio panels; Image: Madhu Kapparath

Shriti Pandey, founder, Strawcture Eco with the agri bio panels; Image: Madhu Kapparath

On July 11 last year, Shriti Pandey stood in front of Vistex Hospital—a Covid-19 hospital—in Masahri Block, Patna, watching its inauguration ceremony. "It took a village, quite literally, to build this hospital," recalls the 29-year-old. Along with her team and residents of the village, Pandey had set up the hospital in under 80 days using a sustainable material—agri bio panels—manufactured by her for-profit venture Strawcture Eco.

"The very next day, patients started coming. It was like they wanted the hospital built yesterday. In the 100 km stretch from Patna to the village, this was the first hospital that was built," she explains. The hospital was made for Doctors For You, a Delhi-based NGO, along with Selco Foundation. Currently, it can accommodate close to 100 beds and has about 11 to 12 doctors. With the situation getting dire in rural India, Doctors For You—the organisation running the hospital—has reached out to Pandey's team to set up another 100-bed hall in order to accommodate more patients.

Her team knew time was less, so they worked simultaneously on many things. "For instance, while the foundation was being built, we did all the prefabrication in the field. So instead of individually connecting things, we made walls, roof and floors off site, like a modular construction," explains Pandey. These were brought to the site to simply connect, once the foundation was ready.

Vistex Hospital in Patna, Bihar, was built last year in June 2020 for Covid-19 patients. The first floor was built using Strawcture's panels and frame