Here's how this company is making India a quality food destination

There were days when food producers and distributors operated within narrow margins while struggling to achieve high-quality standards. Fortunately, automation of the food processing industry is helping raise profits while providing customers with an even better product.

Mr. Sameer Gandhi, MD, Omron Automation, India , writes how automation of the food processing sector is making India a quality food destination by ensuring more income for farmers and food availability.

The Sunrise Sector

Food Processing is one of those sunrise sectors in the country that connect Agriculture with Manufacturing – the two major contributors to the GDP of the country- effectively. This linkage is multidimensional, resulting in the emergence of diverse benefits for varied stakeholders. It helps in reducing the wastage of food in the post-harvest phase considerably, improves the value of the raw agriculture produce, provides a safety net to the farmers against the market swing of prices & enhances their income, boosts manufacturing, facilitates research & development, and also creates more job opportunities.

The demand and supply dynamics in India

India is amongst the leaders for total food production and is the 6th largest food and grocery market globally. On the demand side, the market is highly driven by the expanding population base, the pace of urbanization, rising purchasing power and disposable incomes, swiftly expanding retail trade due to the e-commerce build-up and a significant presence of global players.

Pegged between USD 121-130 bn, the Indian food processing industry accounts for around 30% of the country’s total food market in India, which is growing at a fast pace. The industry is also one of the largest in India in terms of production, consumption, export and expected growth (Source: GranthThorton, Feb 2017)

The sector is perhaps the most appropriate segment for creating jobs for rural poor and thus reduces the burden on the agricultural sector for livelihood creation with the advantage of not having to move people from rural to the already overpopulated urban centers.

The employment intensity can be seen by the fact that for every Rs. 10 lac invested, 18 direct jobs and 64 indirect jobs are created in organized food processing industry alone. (Source: J Food Process Technol Journal, 2013).

Opportunities for the automation sector

With all these positives indicating such an optimistic outlook for the food processing sector for varied stakeholders, there are more opportunities where the automation industry is adding value to help the sector realize its full potential:

• Current levels of technology deployment are way below the global standards and product development and innovation has immense possibilities: Influenced by the ever-changing consumption pattern of the aspirational Indian consumers – the industry needs to keep experimenting and come up with products scoring high on shelf life, variety, convenience, and health.

Food wastage levels need immediate attention: Experts say that only 10 percent of agricultural produce is processed in the country, leading to a lot of wastage; up to 40% of the food produced is inevitable to get wasted. A robust food processing sector can significantly help reduce this wastage and also improve the income level of the farmers.

Human-machine harmony based automation solutions

Industrial automation solutions have an important interface to make the most of the opportunities mentioned above. The technology has immense possibilities for reducing wastage, spurring innovative technology deployment and enhancing productivities at the shop floors of manufacturers, involved in the secondary and tertiary processing stages by:

• Enhancing the efficiency of machines:

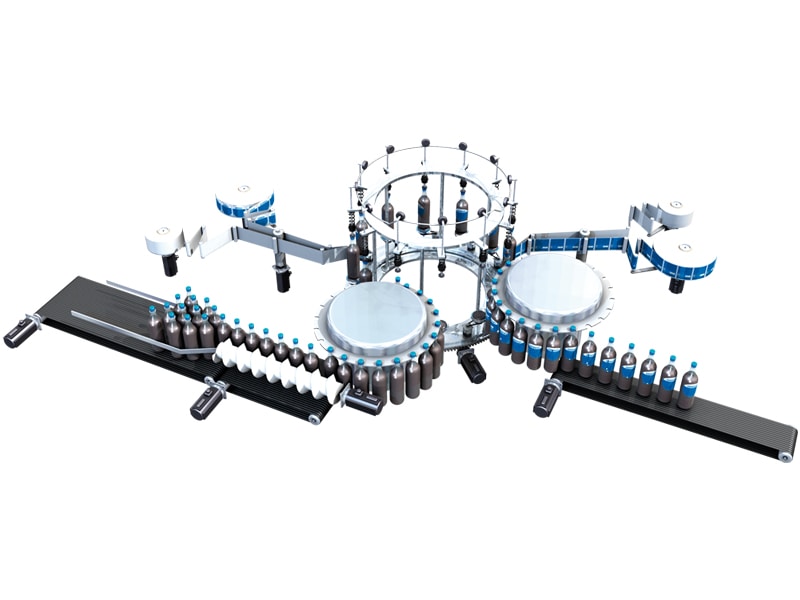

Increasing the speed of the machines is one of the most-pursued ways to enhance the efficiency. However, a maker cannot increase the speed beyond a certain point as it could lead to residual vibrations causing spilling and wastage. Smart automation solutions reduce vibration and prevent spilling, leading to faster machines with improved performance and no wastage at the material handling shop floors.

• Ensuring impeccable sorting & placement:

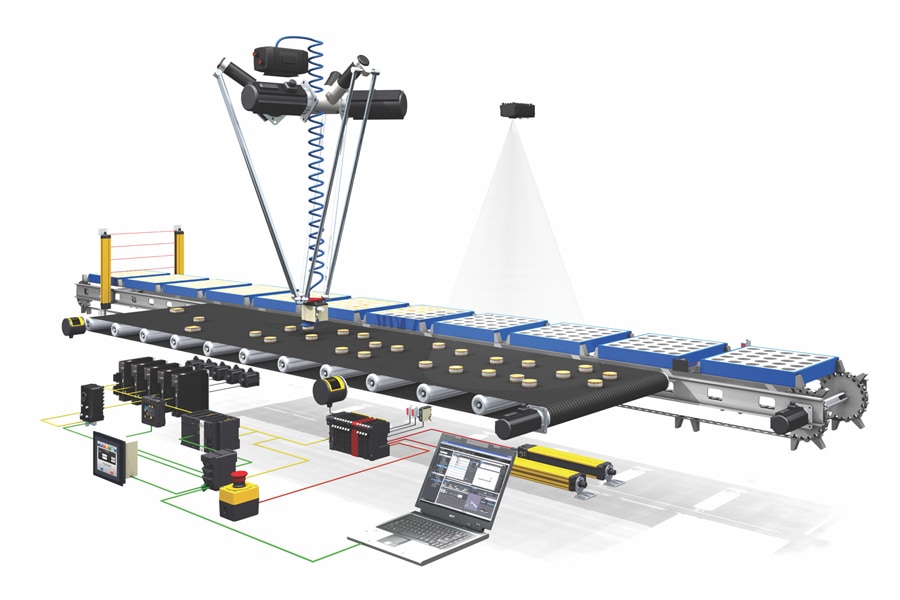

With the increasing demand for more varied packaging, the manufacturers grapple with bottlenecks such as precise product placement, repetitive labor-intensive tasks leading to manual errors, incorrect sorting due to a grayscale vision and machine downtime in changeovers. With controllers, color recognition based vision sensors and robotics, processors can attain 100 % precision in picking and placement with the correct orientation, impeccable sortation of products with varying shapes, colors and sizes, and reliable inspection. Better the level of precision and reliability, lesser is the amount of waste or scrap.

Robots have begun their journey in the food processing sector and are finding immense utility in the material handling sector rendering a lot of flexibility and helping in elevating productivity levels. By end of the year, robotic integration, for these kinds of functions, in the food and beverage sector is expected to grow by 144%.

• Ensuring quality, food safety, and recalls:

With increasing demands on food safety, legislation and public awareness, it is mandatory to eliminate all probabilities of producing unsafe, spoiled or contaminated food. A total traceability system is capable of backtracking every step of the manufacturing process, specifically expiry date extraction verification and specification data. This assumes greater importance as specialized manufacturers produce varied products for multiple brands. Also, the fast-acting temperature controllers at the sealing applications ensure perfect sealing while in motion at high speed.

Making smarter machines with artificial intelligence

With the ever-increasing shift to extremely flexible production lines, machine automation controllers equipped with artificial intelligence (AI) algorithm (real-time control based on high-speed and high-precision data gathering) are making it feasible to control production lines and equipment changing in microseconds to gauge and manage them safely before an irregularity occurs. It also allows manufacturers to contain the impact of skilled worker shortages while simultaneously increasing equipment utilization and achieving stable production of quality products (even remotely). This also allows production centers to be distributed and be closer to the agriculture produce sectors since manufacturers can manage and control these multiple centers remotely.

Looking ahead

A technologically-advanced, automation-enabled food processing sector is a repository to micro as well as macro level benefits contributing towards bigger goals. From managing the wastage to increase in production to even sprucing up the supply chains battling with inefficiencies, the benefits get translated to larger goals such as better market access and remuneration to farmers, rise in employment and export earnings and gradually to a successful second green revolution contributing towards the socio-economic growth of the country.

Disclaimer: This is a sponsored brand story by Omron Automation and the liability for the same solely rests with them.

X