GE Aerospace's soaring ambitions in India

The world's leading aircraft engine maker expects to be in the thick of both India's commercial and military aviation growth

Mohamed Ali, vice president of engineering at GE Aerospace Image: Selvaprakash Lakshmanan for Forbes India

Mohamed Ali, vice president of engineering at GE Aerospace Image: Selvaprakash Lakshmanan for Forbes India

GE Aviation, General Electric's aviation arm, which will soon become an independent company, GE Aerospace, has big plans to ramp up its Indian operations.

The company is seeking to consolidate its position as the engine supplier of choice as India’s commercial airliners place record orders for hundreds of planes with demand for air travel soaring in the subcontinent post Covid.

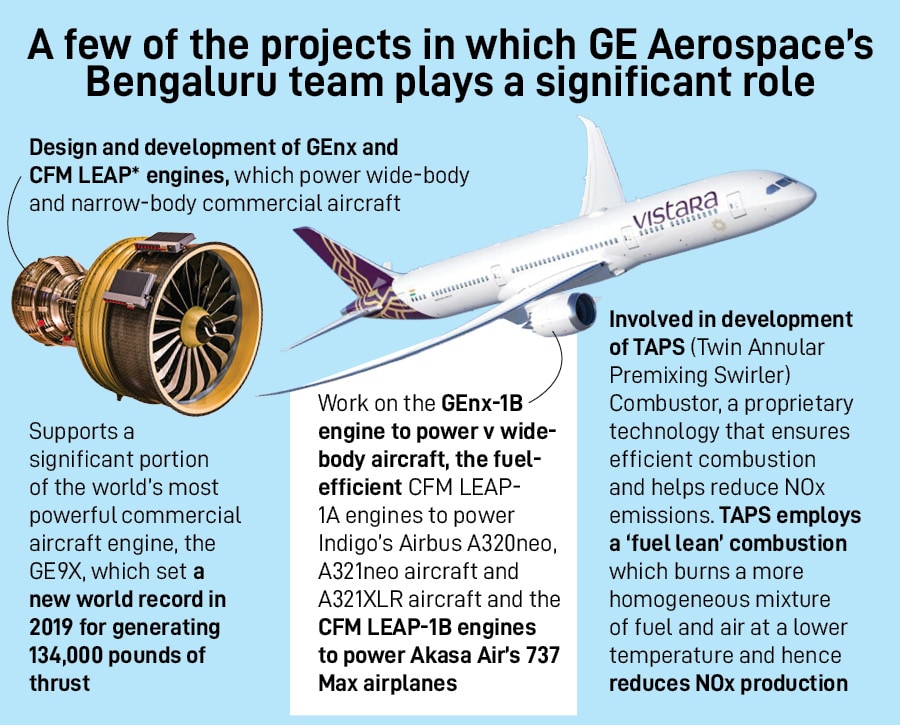

GE Aerospace, whose Indian engineering team already plays a central role in developing its engines, including those that go on the larger, ‘wide-body’ aircraft, expects that India’s airlines will also buy more of such aircraft as international travel picks up too.

But also, on the military front, GE engines are expected to go into India’s second-generation light combat aircraft (LCA). And discussions are reportedly at very advanced stages for GE to help India to make those engines locally, via Hindustan Aeronautics Limited.

Even as this copy goes to print, an important objective for Prime Minister Narendra Modi’s June 22 Washington visit is said to be finalising this deal, according to an exclusive Reuters report.