How SwitchOn automates quality check on the factory floor

With a powerful edge-AI solution, SwitchOn solves the quality inspection problem for large manufacturers

(L to R) Aniruddha Banerjee and Avra Banerjee, co-founders, SwitchOn. Image: Selvaprakash Lakshmanan for Forbes India

(L to R) Aniruddha Banerjee and Avra Banerjee, co-founders, SwitchOn. Image: Selvaprakash Lakshmanan for Forbes India

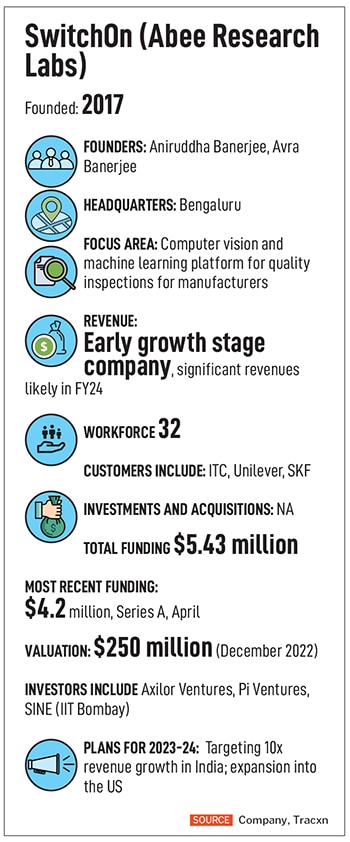

Aniruddha Banerjee and Avra Banerjee are cousins-turned-co-founders with their first software venture, Abee Research Labs, that has found some early success within two years of launching their first product.

As engineers, they collectively bring more than a decade of experience to their startup in areas, including computer vision, Internet of Things and machine learning, and stints in hi-tech engineering companies such as Nvidia—the leader in computer processors for artificial intelligence (AI)—LSI, Schneider Electric and Samsung Electronics.

They discovered that quality inspection processes at some of the world's largest manufacturers are ripe for innovative interventions, as much of those remain manual. To that end, they're building an AI software-based platform at their five-year-old venture under the brand name SwitchOn, integrating camera modules, sensors and so on to help automate sorting out of defective products on the factory floor.

“If you have, for example, a product that has a defect, you essentially have a very bad impression about the brand itself, and even more so for premium products,” says Aniruddha. “Imagine you bought, let's say, a Tresemme shampoo… you definitely would not want their artwork to have a crack in the middle, right? Or some kind of a wrapping issue.”

In working with most of their customers, the founders saw a defect rate of at least 3-4 percent, he says. Therefore, “every minute they are shipping out about five to 10 defective products per line, so just imagine how big the problem is”.

Avra worked at the R&D department at Schneider Electric, located on the outskirts of Bengaluru. He was also among those who literally took a moonshot, working on a lunar lander and a rover at the early Indian private space tech venture Team Indus. He worked on areas, including avionics and electronics, there.

Avra worked at the R&D department at Schneider Electric, located on the outskirts of Bengaluru. He was also among those who literally took a moonshot, working on a lunar lander and a rover at the early Indian private space tech venture Team Indus. He worked on areas, including avionics and electronics, there.