India's potential to dominate smartphone and semiconductor manufacturing for the world

India seems poised to earn its spurs for its manufacturing prowess on the global stage across a bunch of sunrise sectors, from defence to electronics. The Forbes India edition this fortnight has a collection of stories that showcase the potential and opportunity for India in sectors like smartphones and semiconductors

Apple’s plans to utilise India as a manufacturing base for the world also puts the spotlight on the exports potential.

Apple’s plans to utilise India as a manufacturing base for the world also puts the spotlight on the exports potential.

In Narotam Sekhsaria’s The Ambuja Story, (Harper Business 2022) the founder of Gujarat Ambuja Cement (now Ambuja Cements) explains his desire in the early 1980s to evolve from a successful cotton trader to a manufacturer: “Traders, however successful… were never seen as wealth or asset creators… respect, esteem and admiration were always reserved for those who had successfully set up large manufacturing companies.”

Sekhsaria goes on to, in vivid detail, describe the process of setting up a manufacturing base. It’s never easy, and was even more difficult in an era of “extreme socialism”. The first steps involved getting partners/investors on board; organising the debt from development financial institutions (the 700,000-tonne plant had a project cost of ₹80 crore, with a 3:1 debt to equity ratio); handpicking professionals who understood the industry (cement); identifying the right location (close to limestone mines); seeking the help (and blessings) of state and Union governments; getting a licence (remember, this was the Licence Raj era), and identifying a quality and cost-effective supplier of the cement plant and of critical plant equipment like high-tension motors.

Perhaps one of the biggest early challenges was identifying land, of around 225 acres. As Sekhsaria puts it, “Land acquisition for the setting up of an industrial plant is never easy in India, even in the best of times.” His team had identified a sleepy little town in Gujarat called Mahuva in Bhavnagar district, which had ample tracts of land. But there were at least three problems: A local small cement maker who feared being wiped out, the local hooch mafia and a Bombay-based industrialist who owned land nearby and didn’t want any large-scale manufacturing there. After dealing with a series of agitations (with the police having to once resort to firing), Sekhsaria and team gave up on Mahuva and identified Vadnagar in Gujarat’s Junagadh district to set up the plant. It would later become Ambujanagar, and was the stepping stone to what has become today a company with a capacity to make 31 million tonnes of cement across six integrated manufacturing units and eight cement grinding units across the country.

The Ambuja story is inspiring at a time when ‘Make in India’ is the buzzword, and India seems poised to earn its spurs for its manufacturing prowess on the global stage across a bunch of sunrise sectors, from defence to electronics. The Forbes India edition this fortnight has a collection of stories that showcase the potential and opportunity for India in sectors like smartphones and semiconductors.

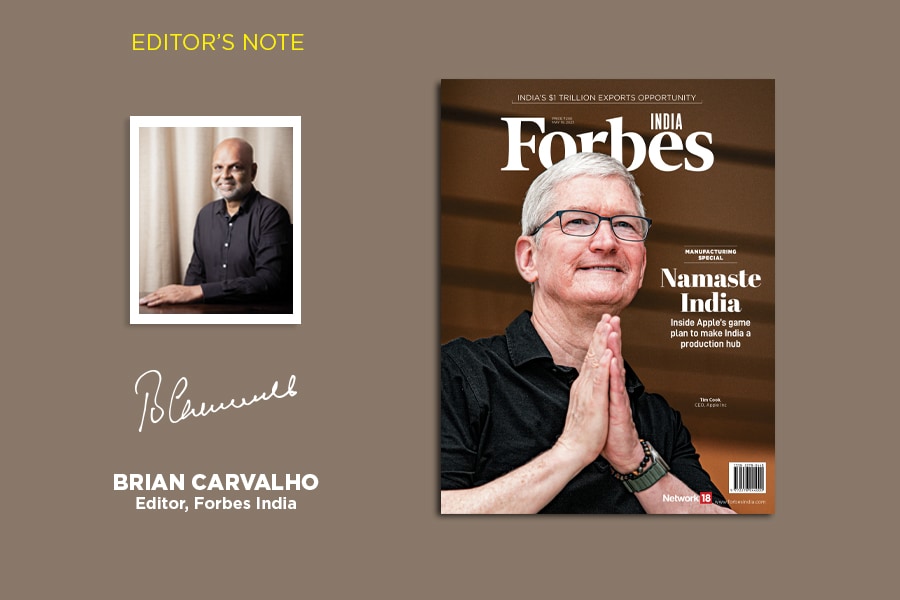

On the cover is Apple Inc CEO Tim Cook, who recently made waves in India when he opened India’s first two Apple stores in Mumbai and New Delhi. The enthusiasm that an iconic brand generates was palpable among the thousands of Apple fanboys and fangirls who thronged the stores; but equally exciting is Cook’s blueprint to manufacture more iPhones out of India. Naandika Tripathi pieces together the game plan to make, sell and export iPhone models from India through three contract manufacturers—Foxconn, Pegatron and Wistron.