How Micro Labs struck gold with Dolo-650 during Covid-19

The company has sold 350 crore tablets since the Covid-19 outbreak in 2020, and earned revenues of Rs 400 crore in a year

Dilip Surana, Chairman and managing director, Micro Labs Ltd.

Dilip Surana, Chairman and managing director, Micro Labs Ltd.

Image: Nishant Ratnakar for Forbes India

Until about two decades ago, the Surana family used to live in a rented home in Bengaluru. Not because they were bogged down by some family dispute or because they couldn’t afford to buy a house. After all, by the mid-1990s, they had already established one of India’s best-known pharmaceutical companies, headquartered in Bengaluru, and manufactured the wildly successful Dolopar tablets. The company had also built a portfolio of drugs, ranging from cardiology to diabetes and psychiatry.

The rather frugal life they lived back then was a conscientious choice, largely because of the family patriarch GC Surana’s firm belief that every penny earned from the business deserved to be ploughed back into the company. There was just no scope or time for extravagance or even comfort.

“My mother would pester him to buy a house, and all he would say was okay, but it took him a long time to come around,” says Dilip Surana, GC Surana’s son. “Whatever money he made, he believed that if he invested in Dolopar, it would double. He didn’t like spending money on things like a house or car, and those things never attracted him. It was all about building the business.”

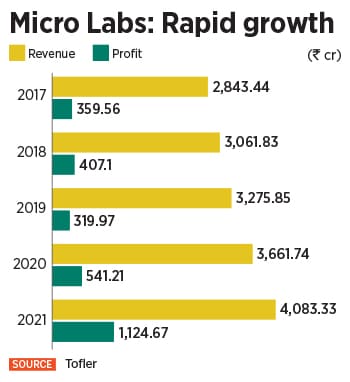

As of October 2021, the Surana brothers, comprising Dilip and Anand Surana, are worth $2.24 billion according to Forbes, making them India’s 94th richest people.

Dilip joined the business in 1983, before taking up a full-time role in 1987, and has since helped shift the company’s South India-based focus to a pan-India one. His brother Anand joined the business and has been steadily focussed on the international market. The company has a presence in over 50 countries, with ground-level operations in 25. “When Anand joined the business, we were doing very little exports to countries like Sri Lanka, Nigeria, and the Middle East,” Dilip says. “Today, we are into all the regulated markets like the US and Europe, and semi-regulated markets and even nonregulated markets.”

Dilip joined the business in 1983, before taking up a full-time role in 1987, and has since helped shift the company’s South India-based focus to a pan-India one. His brother Anand joined the business and has been steadily focussed on the international market. The company has a presence in over 50 countries, with ground-level operations in 25. “When Anand joined the business, we were doing very little exports to countries like Sri Lanka, Nigeria, and the Middle East,” Dilip says. “Today, we are into all the regulated markets like the US and Europe, and semi-regulated markets and even nonregulated markets.”