Meet the GenNext entrepreneurs invigorating their family-business culture

The newer generation in storied companies is unafraid of introducing new ways of running the business. And it's yielding favourable results too

Illustration: Sameer Pawar

Illustration: Sameer Pawar

When Anant Goenka rejoined Ceat in 2010—fresh off his MBA and a stint at KEC, his family’s power transmission business—the tyre-maker had just come out of a rough patch. Sales were finally recovering, high costs were kept in check and the outsourcing business was given a new fillip. “The aspect of survival was over,” recalls Anant, 37, who took over as managing director in 2012. “My predecessor had made some important investments [a greenfield plant and an R&D facility] to take us into the next phase of growth.”

With its freshly found financial footing, Ceat, part of the RPG Group, set up by Anant’s grandfather Rama Prasad Goenka in 1979, would seem an odd candidate for a dramatic cultural overhaul. Yet, that is exactly what the third generation scion did.

Or take the case of Nalli, the nine-decade-old, privately held business synonymous with Kanjeevaram silk sarees. “We’ve always had a culture of operational excellence and entrepreneurship,” says Lavanya Nalli, 34, the founder’s great-great granddaughter. After spending six years away from the business—at Harvard University, McKinsey, and Myntra—she was able to see the hurdles that were holding Nalli back from exponential growth.

In the case of Arvind Ltd too, Sanjay Lalbhai’s sons Punit, 36, and Kulin, 32, entered the business about a decade ago and wanted to move from “being a traditional textiles company to a technology company”, which would require certain processes to be put in place. “It wasn’t so much of a departure from the old way of working,” clarifies Kulin, the fifth generation at the company. “My father grew the business from a denim mill to a textiles conglomerate. So that culture of innovation and creativity has always been there. We’re just enhancing and building on it.”

Anant Goenka, Managing Director, Ceat

Anant Goenka, Managing Director, CeatImage: Mexy Xavier

Whether it’s a large, wholesale change or an incremental tweak, ‘culture’ is slow to build and hard to change, especially for companies with a long and storied history. Unlike a new-age startup that can draw out a manifesto of its values and plaster it on the walls of its offices, or offer free yoga classes and beer bashes to encourage a sense of community and out-of-the-box thinking, decades-old family businesses have it tough. What aspects of the culture should be retained? What should be revitalised so as to better resonate with today’s contexts, customers and employees? And what about older employees—trusted, but used to set ways—who might resist the change?

You need to have a clearly communicated vision when looking to change a company’s culture, and then you need to ensure the vision trickles down to all employees,” says Paul Dupuis, CEO of staffing firm Randstad India.

Anant, for one, vouches for this approach. Although the company stood on firmer ground when he took over, employees’ mindsets were still geared towards quarterly results. “We had perpetuated a making-sure-we-don’t-make-losses kind of mindset, but that was not ambitious enough,” he says. “So we asked ourselves, ‘What can we do over a five-year period that will make us proud?’”

Strategic changes such as diversifying the product mix to focus on tyres for two-wheelers and cars, which have firmer prices and higher pricing power, were necessary, as was a renewed focus on research and development. However, true to the ‘culture eats strategy for lunch’ adage, Anant knew that a vital change in workplace culture was needed for employees to truly internalise the five-year game plan. Briefly trained in the principles of total quality management (TQM), an idea characterised by excellence in managerial, operational and administrative processes developed by a number of Japanese firms in the 1950s and ’60s, Anant decided to put that into effect at Ceat.

Strategic changes such as diversifying the product mix to focus on tyres for two-wheelers and cars, which have firmer prices and higher pricing power, were necessary, as was a renewed focus on research and development. However, true to the ‘culture eats strategy for lunch’ adage, Anant knew that a vital change in workplace culture was needed for employees to truly internalise the five-year game plan. Briefly trained in the principles of total quality management (TQM), an idea characterised by excellence in managerial, operational and administrative processes developed by a number of Japanese firms in the 1950s and ’60s, Anant decided to put that into effect at Ceat.

“It’s not as though we didn’t have processes in place before we took on the TQM journey,” says Raj Moitra, Ceat’s vice president of international business, who joined the business in 2010. “The problem was we had short-term, non-structured views on processes, capacity and product planning, which resulted in high profit variances from one quarter to another. Moreover, while we had brilliant individuals in different departments, it was not seen across the board.”

Ceat’s TQM effort started in 2010 and only picked up steam in 2012. The company’s vision—that of putting the customer at the core—was clearly communicated to employees and ‘quality’ was made the job of every employee, not just the ‘quality controller’ at the end of a production line. This was done by making ‘kaizens’ or small continuous improvements mandatory for everyone, like improving niggles on the manufacturing front or bettering responses to consumer complaints. “There was resistance initially because it required a lot of documentation,” admits Anant. “We really had to spend time educating people to change their mindsets,” he says, adding that he has taken on the task of improving patent-filing at Ceat. Already 25 were filed last year, up from five that had been filed over the last 50 years. In recognition of its changing ways, Ceat snapped up the globally recognised Deming Prize for quality management, last year.

The youngsters at Arvind Ltd, too, are leading from the front. After all, culture change is driven by leadership, points out Tulsi Jayakumar, head of the Family Managed Business programme at SPJIMR.

“You have to establish a need for any kind of innovation, and then create a shared vision to bring it to life,” says Punit, referring to the slew of new areas Arvind has branched into, including ‘technical textiles’ such as fire-protection gear and combat clothing, an ecommerce arm that will draw on machine learning to understand consumer preferences, and a cotton growing venture. To foster innovative, “outside-in” thinking, as Kulin puts it, the brothers set up an innovation cell. Clear communication, clear responsibilities and the ownership of projects is stressed on, says Kulin. “We also have a tolerance for failure. Without that you cannot innovate.” Currently, in-house innovations such as water-free dyeing of fabrics, making clothing from recycled waste, and using man-made fibres in blends are underway.

Lavanya Nalli, Vice Chairman, Nalli

Lavanya Nalli, Vice Chairman, NalliImage: Nishant Ratnakar for Forbes India

At Nalli, on returning to the family business in 2015, Lavanya found that decision-making at the company was mostly gut-based. “It didn’t always lead to the most optimal outcome,” she says. Moreover, because teams weren’t nimble enough, arriving at a decision was often slow and tedious. So she started gathering and looking at data to make more informed decisions, and eventually made that data available to employees. “My McKinsey experience exposed me to how Fortune 500 CEOs think about growth, risks and opportunities. I drew on that at Nalli, but I never told our people that this is how it was done at multinationals. It would create immediate resistance,” explains Lavanya.

Instead, slowly yet deliberately—without trampling on the staff’s innate entrepreneurial spirit—she ensured they had access to the right information, at the right time so that they could take the right decisions. Today, whether it’s about optimising marketing spends or opening a new store, data-based analyses drive all decision-making at the ₹700-crore Nalli.

Lavanya credits this change for the three-fold growth Nalli’s ecommerce division has seen, despite no heavy discounts or marketing spends. Private labels have grown too, including a clothing line for ‘modern women’ to which Lavanya lent her name. “We still have a finger on the pulse of the consumer, and draw on our gut,” she says, “but data helps us identify bottlenecks in the business and quickly work around them.”

Even for a smaller outfit like the Delhi-based Agarwal Packers and Movers, transitioning into a more technology-friendly company can prove difficult. Second generation Navneet Agarwal, 25, wanted to integrate IT into the company’s everyday operations, but his father Ramesh, 56, was sceptical. “He thought of technology as an expense, rather than an investment,” says Navneet. When the senior Agarwal grudgingly relented, Navneet initially piloted a small project of routing all calls received at their call centres across India to a single centre in Delhi, where the staff were trained in best practices. Not only did the number of inquiry calls increase, the conversions doubled as well, says Navneet. Pleased with the outcome, his father allowed him to go full steam ahead with his plans. Today, even field staff use tablets to draw up real-time quotations for goods that need to be packed and transported. “We had to conduct several workshops and training sessions for our staff [to plug the skills gap] but it has all paid off,” says Navneet, adding that his father now insists on launching artificial intelligence-based solutions too. “Now that I’ve seen what technology can do, I’ve become greedy,” chuckles Ramesh.

Among Marwaris and Gujaratis, in particular, where the sons marry early and enter the family business at a young age, the age difference between fathers and sons is not much. So it’s not as though the skills and experience of the older generation are redundant or irrelevant,” says Jayakumar, highlighting the need for pilot projects in such cases.

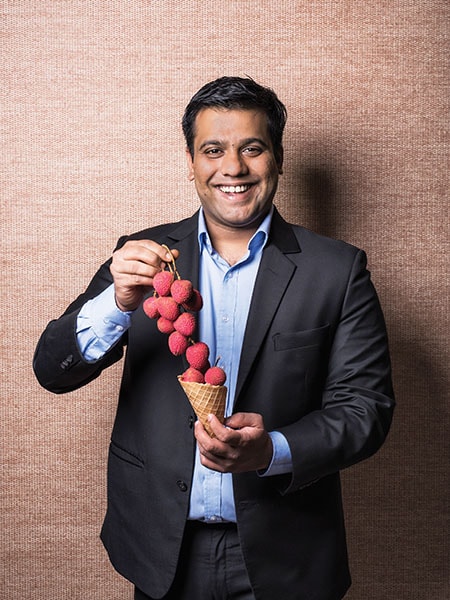

Srinivas Kamath, Director, Natural Ice Cream

Srinivas Kamath, Director, Natural Ice Cream

Equally important is winning the trust of employees, especially older ones who might be sceptical, even resistant, to changes. Srinivas Kamath, 34, second-generation scion of Natural Ice Cream, faced this dilemma when he entered the business in 2009. At the time, the company was largely manufacturing-focussed, leaving the retailing to franchises. But Srinivas found that customer service was not up to the mark at these outlets. “I was sifting through email complaints and found that most read the same: ‘We visited this outlet, the ice cream was great but…’”, recalls Srinivas, shaking his head. “That complete experience for the customer was lacking.”

When explaining this to franchise owners proved difficult, Srinivas set up Naturals’s own parlours (there was only one at the time in Mumbai, compared to 30 franchised outlets). He wanted to create a more aggressive sales and marketing mindset, yet one that kept the customer at the core. But he knew the company’s older employees who had a more “manufacturing and accounting mindset” would not be his torchbearers. So he spun off a separate entity, Kamaths Natural Retail Pvt Ltd, under the parent company, set up a second owned store in Mumbai’s Vile Parle and hired fresh talent from McDonald’s and other QSR chains to learn from their best practices. “We kept the two entities separate so that employees don’t clash and feel threatened by one another,” he says.

The move worked. Better attentiveness to customers led to better sales, so much so that the new outlet raked in double the average daily revenues of franchise outlets, says Srinivas. Seeing the success, older employees eventually came around and started mentoring the newer lot. The latter, in turn, now aspire to positions within the parent company. “For them it’s like a promotion into the main company,” smiles Srinivas, adding that Naturals now has 14 outlets of its own pan-India, and 115 franchised ones. Sales have gone from ₹30 crore in 2009 to ₹195 crore today, of which ₹50 crore comes from the retail arm. Srinivas plans to have one Naturals-owned parlour for every four franchised ones.

The move worked. Better attentiveness to customers led to better sales, so much so that the new outlet raked in double the average daily revenues of franchise outlets, says Srinivas. Seeing the success, older employees eventually came around and started mentoring the newer lot. The latter, in turn, now aspire to positions within the parent company. “For them it’s like a promotion into the main company,” smiles Srinivas, adding that Naturals now has 14 outlets of its own pan-India, and 115 franchised ones. Sales have gone from ₹30 crore in 2009 to ₹195 crore today, of which ₹50 crore comes from the retail arm. Srinivas plans to have one Naturals-owned parlour for every four franchised ones.

Amorphous as it is, culture matters. Not just as a word thrown around in boardrooms or slogans plastered on company walls. Not even because ‘culture eats strategy for lunch’, but because culture is, in fact, strategy.

(This story appears in the 30 November, -0001 issue of Forbes India. To visit our Archives, click here.)