Newtrace Energy: Building deeptech for green hydrogen

The deep-science duo of Prasanta Sarkar and Rochan Sinha is developing a technology offered by only three other companies in the world

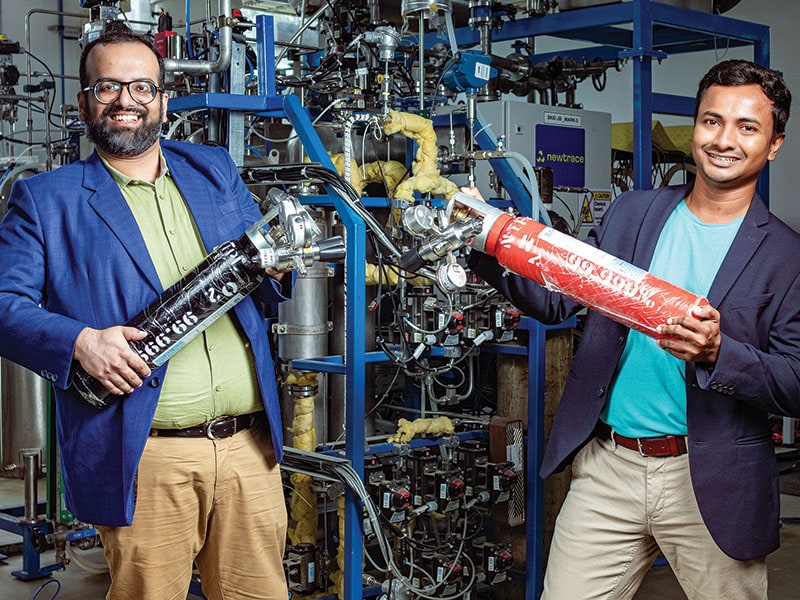

Rochan Sinha (left) and Prasanta Sarkar, co-founders at Newtrace Energy

Image: Nishant Ratnakar for Forbes India

Rochan Sinha (left) and Prasanta Sarkar, co-founders at Newtrace Energy

Image: Nishant Ratnakar for Forbes India

Prasanta Sarkar and Rochan Sinha co-founded Newtrace Energy in 2020 to develop a new class of “membrane-less” electrolysers to produce green hydrogen for industrial customers. Today, most of the 6 to 7 million tonnes of hydrogen produced in the country annually is from fossil fuels.

“There are only three other companies in the world that offer this technology,” says Rajan Anandan, managing director at venture capital firm Peak XV, which led the seed investment in Newtrace last year, alongside Aavishkaar Capital.

The membranes used in the industrial-grade electrolysers need to be highly selective for ions like hydrogen and oxygen, while being chemically stable and durable. Materials that meet these criteria, such as specialised polymers or other advanced materials, are costly to manufacture.

The membranes used in the industrial-grade electrolysers need to be highly selective for ions like hydrogen and oxygen, while being chemically stable and durable. Materials that meet these criteria, such as specialised polymers or other advanced materials, are costly to manufacture.Sarkar and Sinha have developed a proprietary technology that does away with the membrane altogether and uses the flow of water to separate the gases. And their product design and manufacturing largely rely on locally available materials and components in India.

They’ve demonstrated their tech with a near-commercial prototype. Along the way they also decided to focus on higher capacity electrolysers so that they can focus on industrial decarbonisation,which is in large factories like refineries and steel plants.

They’ve established a technology centre in Bengaluru and are working towards a couple of global partnerships. In July, they will be discussing their technology in Stanford, in the US, and they are also collaborating with the Dutch Institute for Fundamental Energy Research in the Netherlands.

Also read: From Aerostrovilos to Bellatrix Aerospace: Deeptech startups, one year on

Some imaginative innovation and inventions have gone into Newtrace’s first electrolyser. For example, they found a way to collect smaller bubbles of hydrogen and oxygen and make larger ones, which helps in reducing the overall footprint of the system. The oxygen detectors they needed weren’t available in the country, so they made their own. Now they are working on hydrogen sensors.

On the commercial front, “we’ll establish the 1 megawatt system and we’re currently building our order book for it”, Sarkar says. Newtrace today has a 20 MW pilot plant that can turn out a few electrolysers. (Electrolyser capacity is typically measured by way of power consumed to generate a kg of hydrogen or other gases).

Sarkar expects the 1 MW electrolyser to hit steady commercialisation by next year. At that point, they plan to design and develop 5 MW and 10 MW capacity products. They’ll need more funding to build a full-scale factory. In the long run, they’ll need to establish a 500 MW or even a 1 GW capacity factory, which would make a dent in the market.

(This story appears in the 12 July, 2024 issue of Forbes India. To visit our Archives, click here.)