Exide Industries Ltd: Always on trend

Kolkata-based company, the country's largest maker of lead acid batteries and power storage solutions, has kept pace with rapidly evolving technology and industry needs

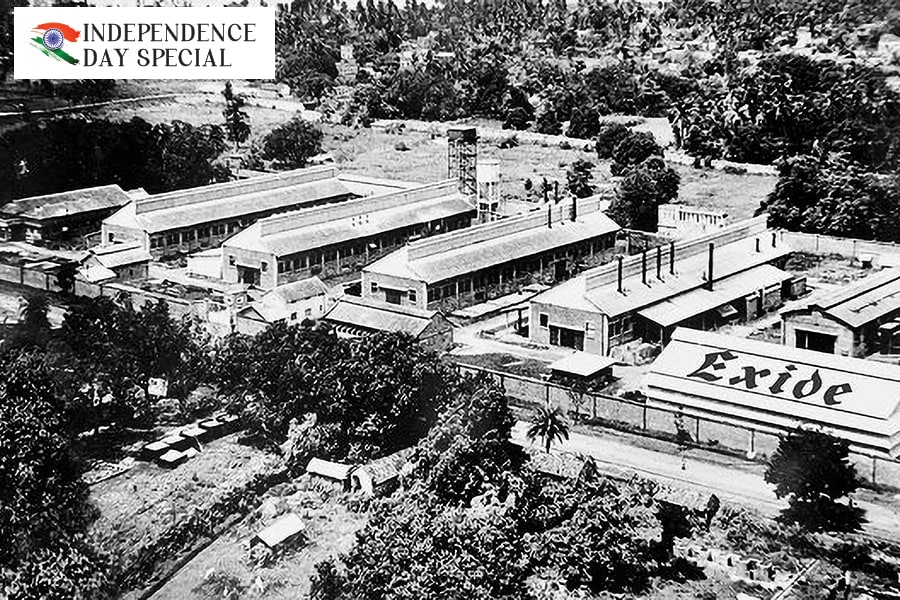

Exide’s first manufacturing plant in Shamnagar near Calcutta (now Kolkata). Image courtesy: Exide Industries

Exide’s first manufacturing plant in Shamnagar near Calcutta (now Kolkata). Image courtesy: Exide Industries

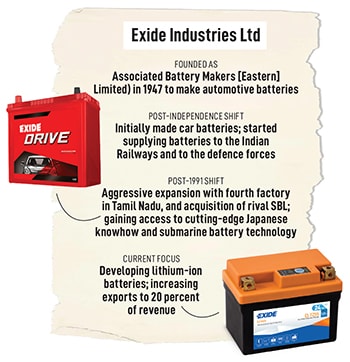

Catching on to industry trends, locating its manufacturing units in close proximity to emerging automotive hubs and reaping the benefits of burgeoning demand, is what the company successfully continued to implement in the following decades. Although ABMEL primarily made batteries for road vehicles, it started charting a parallel track for itself by supplying batteries to the Indian Railways, and, following the war with China in 1962, it doubled its production of special batteries for the defence forces. With the setting up of an original equipment manufacturers’ hub in Chinchwad, near Pune, ABMEL set up its second factory there in 1969.

Although the company remained under its London-based parent Chloride Group, over the next few years, ABMEL, renamed Chloride India Limited in 1972, began to draw strengths from India’s talent pool. It started making the country’s first polypropylene batteries in 1973, and set up a state-of-the-art R&D centre in Kolkata in 1976, its first such centre outside of Europe.

Exide’s fourth factory in Hosur, Tamil Nadu, set up in 1997. Image courtesy: Exide Industries It was in the 1980s that the company made its presence felt significantly in the India growth story, and met significant milestones under its first Indian CMD Jahar Sengupta. It established its third factory at Haldia, a port south of Kolkata, in 1982, with its production targeted to meet the growing export demand from the USSR. The decade also saw Exide batteries become the first indigenous original equipment inside the Maruti 800, which, till then, was built with 100 percent imported components. In 1988, the company was renamed Chloride Industries Limited.

Exide’s fourth factory in Hosur, Tamil Nadu, set up in 1997. Image courtesy: Exide Industries It was in the 1980s that the company made its presence felt significantly in the India growth story, and met significant milestones under its first Indian CMD Jahar Sengupta. It established its third factory at Haldia, a port south of Kolkata, in 1982, with its production targeted to meet the growing export demand from the USSR. The decade also saw Exide batteries become the first indigenous original equipment inside the Maruti 800, which, till then, was built with 100 percent imported components. In 1988, the company was renamed Chloride Industries Limited.

In 1991, the year the Indian economy was liberalised, Chloride Group fully divested its trademark in India and battery manufacturing operations to its Indian management, and the Indian company was renamed Exide Industries Limited (1995), following which it went on an aggressive expansion spree. By now, the southern peninsula was emerging as an automotive hub, with foreign carmakers making a beeline for the Indian market, and Exide, like before, placed itself at the centre of the action. In 1997, it set up its fourth factory on 77 acres in Hosur, Tamil Nadu, to produce valve regulated lead acid (VRLA) batteries, with cutting edge technology from Shin Kobe (an affiliate of Hitachi). In 1998, in a surprise move, Exide took over the assets of its rival Standard Batteries Ltd (SBL), which brought access to submarine battery technology.

The following decade saw Exide move beyond the country’s borders, by acquiring a 100 percent stake in its Singapore subsidiary CBSEA to expand into the Southeast and Far East Asian markets, and a 49 percent stake (later raised to 61 percent) in ABML to gain entry into Sri Lanka. In 2003, it set up a subsidiary Espex Batteries Ltd in Cardiff, UK, to supply industrial batteries to the European markets.

The following decade saw Exide move beyond the country’s borders, by acquiring a 100 percent stake in its Singapore subsidiary CBSEA to expand into the Southeast and Far East Asian markets, and a 49 percent stake (later raised to 61 percent) in ABML to gain entry into Sri Lanka. In 2003, it set up a subsidiary Espex Batteries Ltd in Cardiff, UK, to supply industrial batteries to the European markets.The company continued to keep with evolving technology and industry requirements by entering the home UPS sector in 2011, and the manufacturing of lithium-ion batteries in 2018. It is on track to complete the construction of the first phase of its lithium-ion cell manufacturing project in Bengaluru by the end of FY25.

The company is also aiming to increase the export share of its revenue to 20 percent, from the current 8 percent, over the next few years by increasing its presence in the American and European markets; it exports its products to more than 60 countries. At present, Exide has 10 factories spread across five states in India, along with manufacturing facilities in the UK, Singapore and Sri Lanka.Also read: How the 146-year-old Crompton has managed to stay afloat

In July, the company declared revenues of Rs 4,313 crore for the June quarter, with profit after tax rising by 16 percent to Rs 280 crore.